Highly Efficient GWELL Cast Film Line and its Key Components

Product Features:

EVOH (Ethylene Vinyl Alcohol Copolymer) is a high-performance barrier material, effectively blocking moisture and oxygen.

Common structures include 5-layer, 7-layer, or 9-layer co-extrusion forms, such as PP(PE)/ADH(EVA)/EVOH(PA)/ADH(EVA)/PP(PE).

Uses a distributor or in-mold composite die to precisely control the usage of EVOH, reducing costs while ensuring barrier performance.

Applications:

Food packaging (e.g., frozen food bags, vacuum packaging).

Electronic product packaging (moisture-proof and oxidation protection).

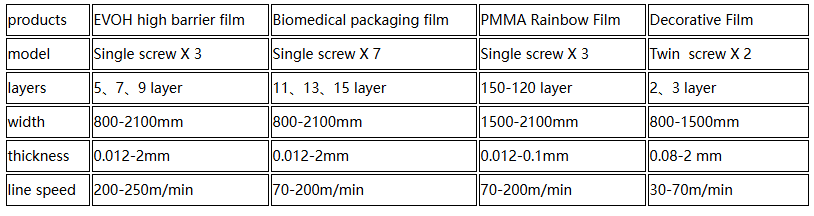

Technical Parameters:

Model: GWS 90/75/65

Layers: 5 layers, 7 layers, 9 layers

Width: 800-2100mm

Thickness: 0.012-2mm

Line Speed: 200-250m/min

Product Features:

Asymmetric cross-sectional design allows for precise adjustment of the thickness and performance of each layer according to specific requirements.

Suitable for biomedical packaging scenarios that demand high barrier properties, high strength, and precise dimension control.

Special production processes ensure the film is flat, without deformation or shrinkage.

Applications:

Medical packaging (e.g., infusion bags, pharmaceutical blister films).

Technical Parameters:

Model: GWS 90/75/120/65/45/90/75

Layers: 11 layers, 13 layers, 15 layers

Width: 800-2100mm

Thickness: 0.012-2mm

Line Speed: 70-200m/min

Product Features:

Composed of multiple layers of plastic film, with up to 150-270 layers, creating a colorful effect through optical interference.

Offers high transparency and excellent optical properties, widely used in decorative and optical fields.

Applications:

Gift packaging, optical decorative materials, specialty display materials.

Technical Parameters:

Model: GWS 90/75/120

Layers: 150-270 layers

Width: 1500-2100mm

Thickness: 0.012-0.1mm

Line Speed: 70-200m/min

Product Features:

PET decorative film adopts a two-layer or three-layer co-extrusion structure, with surfaces offering high gloss or soft "skin-feel" effects.

Suitable for composite use with wood, metal, and plastic substrates in high-end decorative applications.

Applications:

Furniture surface decoration, electronic product casings, interior materials.

Technical Parameters:

Model: GWS P95/52

Layers: 2 layers, 3 layers

Width: 800-1500mm

Thickness: 0.15-0.5mm

Line Speed: 30-70m/min

Product Features:

Manufactured using three-layer co-extrusion technology, PP decorative film is suitable for printing various patterns and offers excellent abrasion resistance and flexibility.

Provides a wide range of width and thickness options to meet diverse decorative needs.

Applications:

Furniture decoration, construction materials, home appliance casings.

Technical Parameters:

Model: GWS 75/90/75

Layers: 2 layers, 3 layers

Width: 800-1500mm

Thickness: 0.08-2mm

Line Speed: 30-70m/min

Multilayer co-extrusion specialty cast films utilize advanced technologies to meet the needs of various fields, including food packaging, biomedical applications, optical decoration, and furniture embellishment. The equipment offers flexible configurations, precise multilayer control, and high-quality solutions tailored to customer requirements.

Contact: Charles

Phone: 18861950103

E-mail: saley@gwell.cn

Whatsapp:+86-18861950103

Add: . 90# Shengfeng Road,Dafeng Economic Develepment Zone,YanCheng ,JiangSu ,China.

We chat