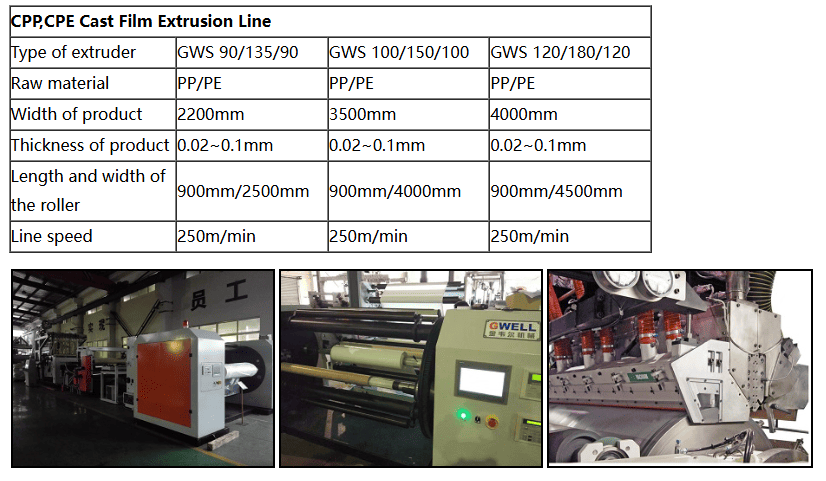

GWELL's CPP/CPE Multi-Layer Cast Film Co-Extrusion Line is an advanced solution for producing high-quality, multi-layered CPP and CPE films. Designed for versatility, it caters to a wide range of applications including food packaging, medical use, and industrial packaging. This line combines high-efficiency production with customizable film widths up to 4000mm and thicknesses ranging from 0.02 to 0.1mm, ensuring adaptability and precision for diverse packaging needs."

The CPP/CPE Cast Film Extrusion Line is a high-efficiency production system used to manufacture cast films made from polypropylene (CPP) and polyethylene (CPE). These films are widely used in packaging for food, consumer goods, medical products, and more. The line employs single or multi-layer co-extrusion technology, and with the use of a multiplier, it can produce up to 72 layers of cast film. This line is equipped with fully imported metering pumps and a digital control system, ensuring precise material input and reduced production costs.

Extruder: The core component of the system, responsible for melting and extruding the raw materials (such as polypropylene or polyethylene) into a cast film. The extruder may use either a single-screw or twin-screw design to ensure even melting of the materials.

Die Head (Co-extrusion Die): The die head is used to extrude the molten plastic material into a thin film. The co-extrusion die is designed to handle single-layer or multi-layer film production. The multi-layer co-extrusion die allows up to 72 layers to be formed, depending on the specific needs of the product.

Multiplier (Multilayer Die): This device enables the production of multi-layer films. By using a multiplier, the system can create films with multiple layers that serve different functional purposes (e.g., barrier, protection, decoration), which can be vital for high-performance packaging.

Cooling Rolls: After extrusion, the film is quickly cooled and solidified by passing over a set of cooling rolls. These rolls help control the film's thickness and uniformity, as well as its surface smoothness and mechanical properties. Cooling can be done through water or air cooling, depending on the product's requirements.

Winding Unit: The cooled film is then wound into rolls for easy handling, further processing, and shipping. The winding unit typically includes an automatic tension control system to ensure that the film does not stretch or tear during winding.

Metering Pumps and Digital Control System: These components ensure the accurate feeding of materials into the extrusion system. The metering pumps allow for precise control of the material proportions, while the digital control system manages parameters such as temperature, pressure, and speed to maintain consistent film quality.

Raw Material Preparation: The raw materials (CPP or CPE pellets) are mixed with additives (e.g., plasticizers, stabilizers, colorants) according to a specified formula.

Extrusion and Melting: The raw materials are fed into the extruder, where they are melted and forced through the die to form a thin film.

Co-extrusion and Layer Formation: The molten materials are extruded through the co-extrusion die to form multi-layer films. Each layer can have different compositions and thicknesses to meet specific product requirements.

Cooling and Solidifying: The extruded film is rapidly cooled on the cooling rolls, solidifying into a thin, flexible film with the desired properties.

Winding and Cutting: The cooled film is wound into rolls for storage and further processing. In some cases, the film can be cut into custom sizes according to customer specifications.

Multi-Layer Co-Extrusion Technology: The line can produce multi-layer films with up to 72 layers, allowing for advanced film designs with varying properties such as barrier protection, heat resistance, UV resistance, and more. This versatility makes it ideal for high-end packaging applications.

Precise Material Control: With the use of imported metering pumps and a digital control system, the production line ensures precise material input, leading to consistent film quality and minimizing material waste.

High Production Efficiency: The CPP/CPE cast film extrusion line is capable of producing films at high speeds while maintaining uniformity and high quality, leading to reduced production costs and increased efficiency.

Customizable Film Properties: The line offers flexibility in adjusting the number of layers, film thickness, transparency, barrier properties, and other characteristics based on the specific requirements of the product.

Energy Efficiency: Modern CPP/CPE cast film extrusion lines are designed to be energy-efficient, with features such as energy-saving motors and intelligent control systems that reduce power consumption during production.

Food Packaging: CPP/CPE cast films are commonly used in the packaging of a wide range of food products, such as bread, biscuits, candies, dried fruits, and frozen foods. The films provide high transparency, excellent barrier properties, and good sealing performance.

Consumer Goods Packaging: These films are also ideal for packaging non-food products like sanitary napkins, diapers, cosmetics, and household items, where durability and moisture resistance are crucial.

Medical Packaging: The line can produce films suitable for sterile medical product packaging, ensuring the safety and hygiene of pharmaceuticals, medical devices, and equipment.

Industrial Uses: CPP/CPE films are also used for industrial packaging, providing protection for various items from environmental factors such as moisture and dust.

Eco-friendly Packaging: With increasing environmental awareness, there is a growing demand for recyclable and eco-friendly packaging solutions. CPP/CPE films are designed to meet these needs, offering a sustainable packaging option for a variety of industries.

The CPP/CPE Cast Film Extrusion Line offers a versatile, high-efficiency solution for producing multi-layer cast films with excellent barrier properties, durability, and customizability. This line is ideal for a wide range of industries, including food, medical, consumer goods, and more. With advanced features such as multi-layer co-extrusion, precise material control, and energy efficiency, it meets the growing demand for high-quality and cost-effective packaging solutions.

Contact: Charles

Phone: 18861950103

E-mail: saley@gwell.cn

Whatsapp:+86-18861950103

Add: . 90# Shengfeng Road,Dafeng Economic Develepment Zone,YanCheng ,JiangSu ,China.

We chat