The ASA, PETG, HIPS, PP Cast Film Co-Extrusion Line by GWELL is a cutting-edge solution for producing a variety of high-quality plastic films. This versatile line is perfect for diverse applications, from building materials to packaging, thanks to its ability to process multiple materials like ASA, PETG, HIPS, and PP. With advanced equipment including extruders, calenders, and cooling systems, it ensures precision and efficiency in film production."

Our decorative film production lines specialize in manufacturing high-quality decorative films using a range of materials including ASA, PETG, HIPS, and PP. Each material has its own unique properties, making them suitable for different applications in industries such as automotive, home appliances, electronics, and packaging.

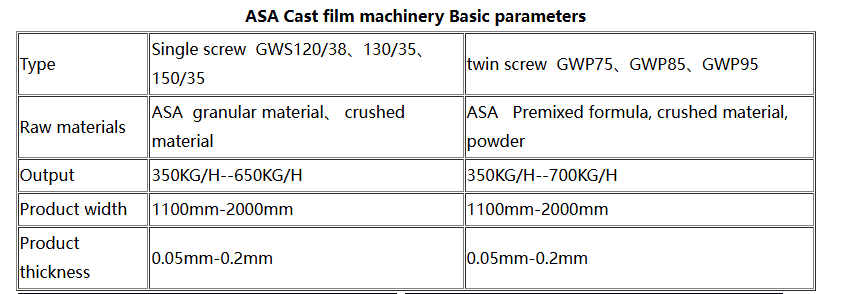

ASA (Acrylonitrile Styrene Acrylate) is a high-performance thermoplastic known for its excellent weather resistance, UV stability, and high-temperature endurance. ASA films are ideal for outdoor applications, automotive exterior parts, and architectural decorations.

Features:

Superior Weather Resistance: ASA films have outstanding UV resistance, making them ideal for outdoor exposure without fading or degradation.

Impact Resistance: These films offer high impact strength and are durable even under harsh conditions.

Smooth and Glossy Finish: ASA films provide a high-quality, glossy surface suitable for premium decorative applications.

Chemical Stability: ASA films are resistant to oils and chemicals, making them perfect for demanding environments.

Applications:

Automotive exterior parts

Outdoor advertising

Architectural decorative materials

Home appliance panels

PETG (Polyethylene Terephthalate Glycol) is a modified polyester material that offers excellent transparency, surface smoothness, and easy thermoforming. PETG films provide high-end visual effects and are used in applications where both aesthetics and durability are required.

Features:

High Transparency: PETG films are highly transparent, making them ideal for clear, glossy decorative applications.

Excellent Processability: PETG is easy to thermoform, print, and coat, allowing for versatile production.

Impact Resistance: PETG films are known for their high impact strength, making them durable and long-lasting.

Eco-friendly: PETG is recyclable, offering an environmentally friendly packaging and decorative solution.

Applications:

Electronics (mobile phones, TV screens, etc.)

Commercial display and advertising materials

Automotive interior parts

Home appliance housings

HIPS (High Impact Polystyrene) is a modified version of polystyrene that offers excellent impact resistance and processability. HIPS films are widely used for cost-effective, large-scale production, while still meeting the requirements for attractive decorative finishes.

Features:

Good Impact Resistance: HIPS films offer strong resistance to physical impacts, reducing the risk of breakage or cracking.

Easy Thermoforming: HIPS can easily be thermoformed into complex shapes, making it ideal for detailed decorative applications.

Cost-Effective: HIPS films are economically viable and suitable for large-volume production runs.

Smooth Surface and Printable: The smooth surface of HIPS makes it ideal for printing custom designs and patterns.

Applications:

Home appliance panels

Electronics housings

Automotive interior decorations

Commercial displays and signage

PP (Polypropylene) is a versatile thermoplastic material known for its chemical resistance, high temperature tolerance, and recyclability. PP films are used in a wide range of decorative applications, especially where durability and environmental sustainability are important.

Features:

Chemical Resistance: PP films offer excellent resistance to a wide range of chemicals, including acids, bases, and oils.

Lightweight and Durable: PP films are lightweight yet durable, making them suitable for various decorative applications.

Good Thermoforming Properties: PP can be easily processed and molded into intricate shapes for decorative uses.

Recyclable: PP is a highly recyclable material, making it an eco-friendly option for manufacturers.

Applications:

Automotive interior and exterior parts

Home appliance panels and housings

Packaging materials with decorative features

Personal care product packaging

These materials are used in advanced decorative film production lines that typically include the following key components:

Extruder: Melts and extrudes raw plastic pellets into thin films.

Cooling System: Rapidly cools the extruded film to ensure uniformity and stability.

Printing Equipment: Some production lines are equipped with printing capabilities to add custom designs, logos, or patterns to the films.

Surface Treatment Equipment: Includes coating or laminating processes to enhance film durability and aesthetic appeal.

Cutting and Winding: The finished films are cut to size and wound into rolls for easy handling, transport, and further processing.

Our ASA, PETG, HIPS, and PP decorative film production lines offer versatile solutions for producing high-quality decorative films with excellent durability, aesthetics, and functionality. Whether you are looking for weather-resistant films for outdoor use, transparent films for high-end electronics, or cost-effective solutions for large-scale production, our production lines can meet a wide range of industry needs, from automotive to home appliances to packaging.

Contact: Charles

Phone: 18861950103

E-mail: saley@gwell.cn

Whatsapp:+86-18861950103

Add: . 90# Shengfeng Road,Dafeng Economic Develepment Zone,YanCheng ,JiangSu ,China.

We chat