In the packaging industry, PVC and PVDC cling films play a pivotal role, especially in the realm of food packaging solutions. These films are integral in daily life, offering a balance of practicality and efficiency. The significance of "PVC cling film" and "PVDC cling film" lies in their multifaceted utility, catering to the diverse needs of modern food packaging.

Overview:

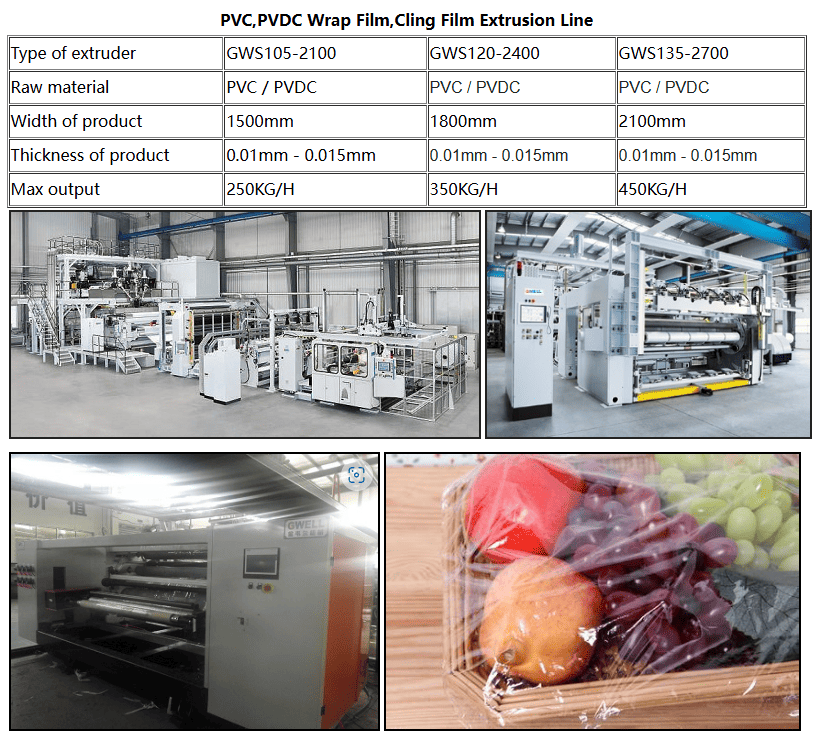

The PVC cast film extrusion line is specifically engineered to produce PVC cling films used in a wide range of packaging applications. This advanced production line creates high-quality films that exhibit excellent clarity, flexibility, and stretchability. PVC films are commonly used for food packaging, protecting products from contamination, moisture loss, and oxidation, thus extending shelf life and preserving quality.

Key Features:

High Transparency: PVC films are exceptionally clear, which enhances product visibility, making them ideal for food packaging where consumers require an unobstructed view of the product.

Excellent Stretchability and Adhesiveness: PVC cling film has excellent stretch properties, ensuring a tight, secure wrap around products. Its high tackiness ensures that the film adheres well to surfaces, reducing the need for additional sealing mechanisms.

Moderate Oxygen and Moisture Permeability: The film allows controlled transmission of gases and moisture, ensuring that perishable goods are kept at the optimal moisture level, while still providing a breathable environment that prevents condensation.

Temperature Resistance: PVC cling film can withstand temperatures between -20°C and 80°C, making it suitable for short-term refrigeration and ambient use. However, it is not designed for high-heat applications such as cooking or microwave use.

Economical and Sustainable: PVC films are highly cost-effective and can be produced in large quantities, making them an economical solution for bulk packaging needs. However, due to environmental concerns, some manufacturers are transitioning to more eco-friendly alternatives like biodegradable films.

Applications:

Food Packaging: Ideal for fresh produce, dairy products, baked goods, meats, and processed foods. The film ensures product freshness and hygiene during storage and transportation.

Retail and Household Use: PVC cling film is often used for food preservation at home, providing a convenient way to wrap leftovers, fruits, vegetables, and meats.

Industrial Applications: Used in packaging non-food products, such as electronics, textiles, and toys, where clear visibility is important.

Market Trends:

With increasing environmental awareness, there is a shift toward using recyclable or biodegradable alternatives to traditional PVC. However, PVC cling film remains popular in many regions due to its cost-effectiveness and excellent performance.

Overview:

The PVDC cast film extrusion line is designed to produce high-performance PVDC cling films, known for their superior barrier properties. PVDC films offer exceptional protection for moisture-sensitive and oxygen-sensitive products, ensuring long-term preservation of food quality. Due to its outstanding performance, PVDC film is often considered a premium solution in food packaging, particularly for fresh meat, seafood, and processed foods.

Key Features:

Superior Moisture Barrier: PVDC cling films have an exceptionally low moisture permeability, preventing the evaporation of water from food products. This is crucial for maintaining the texture, flavor, and nutritional value of perishable items.

Excellent Oxygen Barrier: PVDC films provide an exceptional barrier to oxygen, significantly reducing the risk of oxidation, discoloration, and spoilage, which is especially important for meats and seafood.

Temperature and Chemical Resistance: PVDC films are capable of withstanding a wide temperature range from -60°C (freezing) to +140°C (microwave heating). This makes them suitable for both frozen food storage and microwaveable food packaging.

Non-Toxic and Safe: PVDC films are non-toxic and meet stringent safety standards for food contact, ensuring consumer safety. They are FDA-approved for food packaging in many regions.

High Durability and Strength: PVDC films are stronger and more durable than traditional PVC films, offering better puncture resistance and higher performance in demanding packaging applications.

Applications:

Premium Food Packaging: Ideal for packaging meat products, seafood, cheese, and other temperature-sensitive and high-value foods. The high barrier properties keep products fresher for longer periods, reducing spoilage and waste.

Microwaveable Food Packaging: Due to its high heat resistance, PVDC film is used to package microwaveable ready-to-eat meals, allowing the food to be reheated without compromising quality.

Frozen Food Packaging: PVDC’s low moisture permeability makes it perfect for packaging frozen foods, preventing freezer burn and preserving the texture and flavor of the food.

Medical and Pharmaceutical Packaging: PVDC is also used in medical packaging for its excellent barrier properties, which protect sensitive products from moisture, oxygen, and contaminants.

Market Trends:

PVDC films are increasingly being adopted for high-end food packaging, particularly in the premium food segment. As consumer demand for fresh, high-quality food products continues to grow, PVDC’s role as a leading packaging material is expected to expand, especially in markets with stringent food safety regulations. The increasing trend of convenience foods and ready-to-eat meals also drives the demand for PVDC-based packaging.

Environmental Considerations:

Though PVDC offers excellent preservation qualities, it is not as widely recyclable as PVC. Manufacturers are exploring ways to reduce environmental impact by using alternative polymers or developing recyclable PVDC films to align with global sustainability goals.

By investing in the latest PVC and PVDC cast film extrusion lines, businesses can meet the evolving demands of food packaging, enhancing product quality, freshness, and shelf life. Whether for general use or premium applications, both materials offer distinct advantages, enabling manufacturers to select the optimal solution based on specific requirements and market trends.

Contact: Charles

Phone: 18861950103

E-mail: saley@gwell.cn

Whatsapp:+86-18861950103

Add: . 90# Shengfeng Road,Dafeng Economic Develepment Zone,YanCheng ,JiangSu ,China.

We chat