GWELL's High-Capacity PET and PLA Sheet Extrusion Lines are cutting-edge solutions for the production of premium-quality plastic packaging materials. These lines are engineered for maximum efficiency and feature advanced technology, including a Single Screw Sheet Extrusion Line with Crystallization and Dehumidifier, and a Twin Screw Production Line for PET and PLA without a dehumidifier. Producing sheets with exceptional clarity, strength, and chemical resistance, they are ideal for a wide range of applications in industries such as food, cosmetics, toys, and printing. With a capacity of up to 1500 kg/h and widths up to 1800mm, these lines are globally recognized and operational in countries like Hungary, Jordan, Germany, and America, setting new standards in plastic sheet production.

The GWELL PET sheet extrusion production line is a key strategic product for the company's continuous improvement. It provides highly efficient, energy-saving, and intelligent PET sheet production solutions. Our production lines are widely used for the production of various PET sheets, including APET, PETG, RPET, and others, serving industries such as food packaging, medical packaging, electronic product housings, thermoforming, and gift packaging. With continuous technological innovation, GWELL offers advanced, eco-friendly, and automated equipment to ensure our leading position in the market.

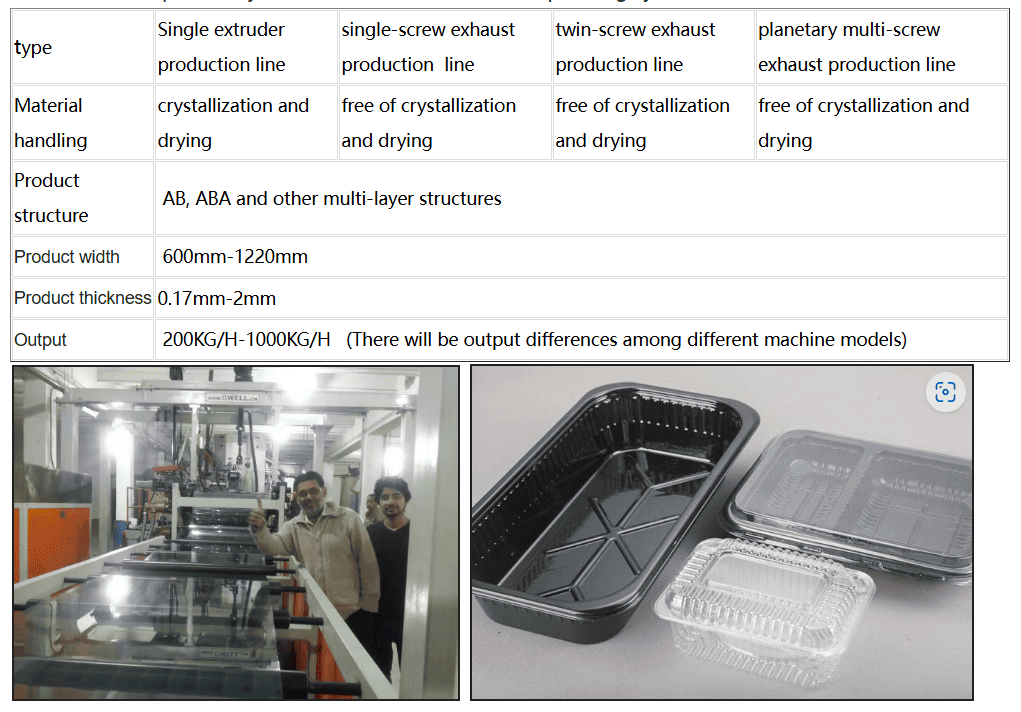

PET Sheet Single-Screw Extrusion Line

Application Areas: APET, PETG, CPET sheet production, widely used for food packaging, pharmaceutical packaging, electronic product housings, etc.

Technical Features: A mature production process with stable performance. The line usually uses a single or double-machine co-extrusion system, ensuring high production efficiency and excellent product quality. GWELL's innovative technology increases the overall efficiency of this model by 30%, enhancing both production efficiency and product stability.

PET Sheet Single-Screw Exhaust Extrusion Line

Application Areas: Suitable for deep cup thermoforming products, food containers, etc.

Technical Features: No need for drying, only crystallizing PET. This process is simple, energy-efficient, and low-maintenance. It ensures the production of deep thermoforming products, such as 18 cm deep cups, while reducing production costs and simplifying the process.

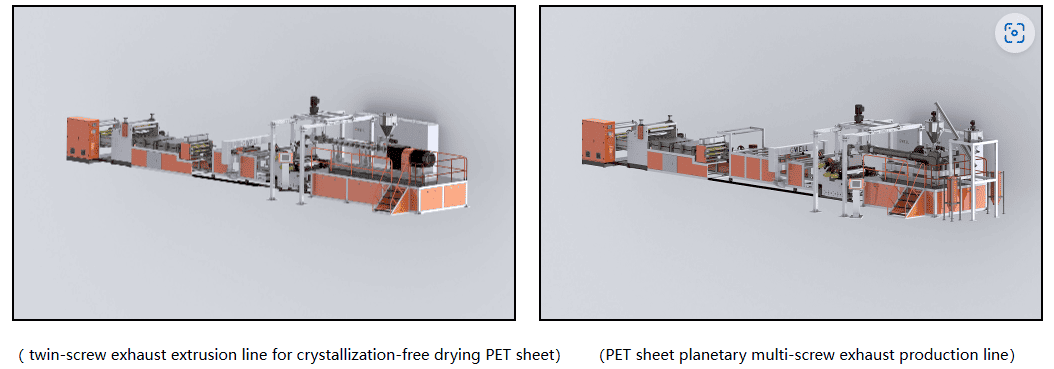

PET Sheet Twin-Screw Exhaust Extrusion Line (No Crystallization or Drying Required)

Application Areas: High transparency and high toughness PET sheet production, widely used in electronic product housings, medical packaging, etc.

Technical Features: The system uses a Roots-rotary vane pump vacuum system that significantly improves the vacuum degree to 10Pa. This enhances the transparency and toughness of PET sheets and boosts production efficiency. The line also requires no crystallization or drying, saving energy and optimizing production processes. The control system, independently developed by GWELL, simplifies operation and ensures efficient production.

PET Sheet Planetary Multi-Screw Exhaust Extrusion Line (No Crystallization or Drying Required)

Application Areas: Multi-layer co-extruded PET sheets, such as APET/PETG, PETG/APET/PETG, etc., widely used in thermoforming, printing, hardware packaging, gift packaging, etc.

Technical Features: The line uses a planetary screw extruder, which increases the material's contact area with air, improving production efficiency. The multi-extruder co-extrusion technology ensures the production of high-quality, multi-layer composite PET sheets. The line supports multiple layer combinations, providing high mechanical strength, toughness, and weather resistance. Equipped with precision distributors and digital displays, this system ensures even layer distribution and adjustable ratios for various applications.

Intelligent Control: The entire system is controlled by Siemens PLC, enabling automated control, real-time parameter monitoring, and optimization of production processes for high-efficiency and stable operations.

Technological Advantages and Innovations

Technological Advantages and InnovationsHigh Efficiency and Energy Saving: GWELL’s production lines utilize energy-saving technologies, especially the no-crystallization and no-drying systems, which reduce energy consumption and align with green manufacturing standards.

Eco-Friendly Materials: The lines support processing of RPET (Recycled PET) materials, offering sustainable production solutions that reduce environmental impact and lower production costs.

High Transparency and Toughness: GWELL's innovative design and vacuum system enhance the transparency and toughness of the PET sheets, meeting the high-quality demands of advanced markets.

Intelligent Automation: With Siemens PLC control systems, the production process is fully automated, reducing manual intervention, increasing production efficiency, and ensuring product consistency.

Multi-Layer Co-Extrusion Technology: The multi-layer co-extrusion technology allows for the production of PET sheets with enhanced functional properties, such as improved barrier properties, UV resistance, and oxidation resistance, making them ideal for a wide range of specialized applications.

GWELL PET sheet extrusion production lines are widely used in the following industries:

Food Packaging: Transparent packaging sheets, thermoformed containers, food packaging.

Medical Packaging: High-transparency, UV-resistant packaging for pharmaceuticals and medical devices.

Electronic Product Housings: PET sheets with high transparency and toughness for use in electronic product casings.

Gift Packaging: High-quality packaging for gifts, electronics, and luxury items.

Automotive Industry: PET sheets used for automotive parts packaging and protective films.

Building Materials: Green building materials, multi-layer composite PET sheets for window protection films, exterior wall decorative films, etc.

Use of Eco-Friendly Materials and Sustainable Production

With increasing awareness of environmental protection and sustainability, more companies are adopting RPET (Recycled PET) to replace traditional PET materials. GWELL’s production lines support RPET processing, providing eco-friendly solutions that lower production costs and reduce environmental impact.

Smart Manufacturing and Industry 4.0

The trend toward Industry 4.0 has made intelligent manufacturing a key focus. GWELL’s PET sheet production lines are equipped with Siemens PLC control systems, ensuring that production processes are fully automated and optimized. This enhances efficiency and ensures stable, high-quality production.

Growing Demand for High-Quality Transparent Sheets

As consumer demand for higher-quality packaging increases, transparency and toughness are becoming key factors for PET sheets. GWELL’s production lines are designed to meet these requirements, providing sheets with superior transparency, toughness, and uniformity to meet the needs of high-end markets.

Energy-Saving and Low-Carbon Technologies

As energy crises and environmental concerns grow, energy-saving and low-carbon production technologies are becoming essential. GWELL’s production lines feature energy-efficient technologies, including no-crystallization and no-drying systems, which help reduce energy consumption while increasing production efficiency, aligning with global environmental goals.

GWELL PET sheet extrusion production lines, with their high efficiency, energy savings, and smart technology, are widely used across multiple industries. Through continuous technological innovation, GWELL provides sustainable production solutions that help businesses improve efficiency, reduce costs, and meet growing market demands. Whether for food packaging, medical packaging, electronic product housings, or the automotive industry, GWELL offers customized production equipment that helps companies stand out in the global market.

Feel free to visit our website for more information, or to schedule a visit for a technical exchange!

Contact: Charles

Phone: 18861950103

E-mail: saley@gwell.cn

Whatsapp:+86-18861950103

Add: . 90# Shengfeng Road,Dafeng Economic Develepment Zone,YanCheng ,JiangSu ,China.

We chat