Our PVDF Film Extrusion Line is a cutting-edge solution for producing high-quality PVDF films, renowned for their durability, thermal stability, and resistance to chemicals and environmental factors. This versatile line includes models like GWS65, GWS75, and GWS90, tailored to meet diverse production needs, with capabilities in manufacturing solar backboard, decorative, filtering, and piezoelectric films. Engineered for precision and efficiency, our line is ideal for industries seeking advanced film technology for a variety of critical applications.

Applications:

PVDF film (Polyvinylidene Fluoride film) is widely used in the production of solar backsheet composites as a protective material for photovoltaic (PV) modules. It offers excellent aging resistance, UV stability, and corrosion resistance, effectively extending the lifespan of solar cells. In addition to its use in the photovoltaic industry, PVDF film is also used in seawater desalination, wastewater treatment, lithium battery separators, and outdoor building membrane engineering.

Production Line Description:

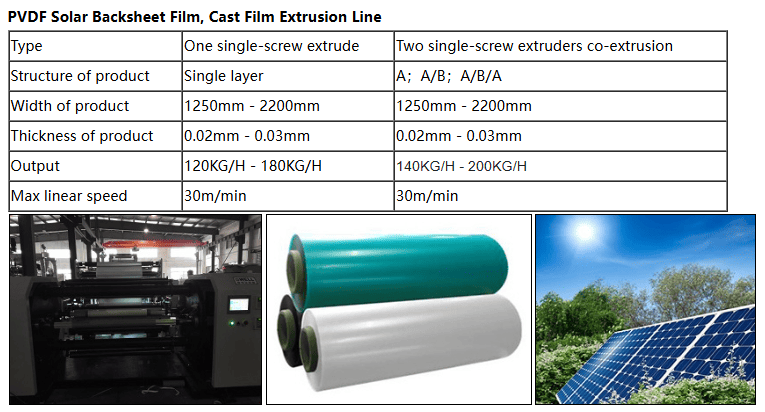

PVDF film (scientifically known as Polyvinylidene Fluoride film) is a high-performance membrane material with outstanding chemical resistance, aging resistance, and thermal stability. Our company offers several models of PVDF solar backsheet film production lines to meet different specifications and production capacity requirements:

GWS75 Model Production Line:

Suitable for producing PVDF cast films with a thickness of 25-30μm and a width of 1250mm. The production speed is 20m/min, with an output capacity of up to 120KG/h.

GW90 Model Production Line:

Suitable for producing PVDF solar backsheet films with a thickness of 25-30μm and a width of 1250mm. The production speed is 30m/min, with an output capacity of up to 180KG/h.

GWS120 Model Production Line:

Suitable for producing PVDF silicon wafer acid-washed thick sheets with a thickness of 1-10mm and a width of 1250mm. The output capacity is around 350KG/h.

Common Characteristics of PVDF and PWDF Films:

Both PVDF and PWDF films are fluorine-based or fluorocarbon-based copolymers, which have superior chemical bonding and structural stability compared to other polymers. This results in the following key characteristics:

High Chemical Stability: These films do not react with contaminants in the atmosphere and are resistant to even highly corrosive solvents.

UV Resistance: They do not undergo structural changes when exposed to UV light, and prolonged sun exposure will not accelerate aging.

Wide Temperature Adaptability: These films can withstand temperature variations from -70°C to +110°C, making them suitable for use in most outdoor environments around the world.

Corrosion Resistance and Aging Resistance: They effectively protect metal surfaces from rust and prevent fading or brittleness of decorative surfaces.

High Abrasion Resistance: PVDF films offer excellent wear resistance, making them ideal for high-wear environments.

Main Applications:

Solar Backsheet Film Production Line: Used in solar module backsheets, primarily for aging and wear resistance to protect the solar cells over time.

Outdoor Decorative Film Production Line: Used for protecting outdoor buildings, glass, facades, windows, and outdoor signage, ensuring long-term durability and resistance to aging and wear.

Battery Separator Film Production Line: Used in fuel cells and lithium-ion polymer battery separators to enhance battery efficiency and safety.

Water Treatment Film Production Line: Used in water purification, including ultrafiltration and microfiltration membranes for wastewater treatment and seawater desalination, removing large molecules, bacteria, sand, salt, and other impurities.

Piezoelectric Film Production Line: PVDF piezoelectric films have a wide frequency response, large dynamic range, high sensitivity to force-to-electricity conversion, and are widely used in sensors, acoustics, and other applications.

Quality Assurance & Validation:

Our PVDF films have been successfully validated in various fields, with uniform thickness, high precision, and stable performance. Multiple companies have achieved large-scale production of PVDF films, receiving full market validation.

Overview:

The Polyolefin Solar Backsheet Production Line is used to produce polyolefin-based materials for solar backsheets. These materials play a crucial role in photovoltaic cell modules. Polyolefins (such as polyethylene and polypropylene) offer excellent weather resistance, UV stability, and moisture resistance, making them ideal for solar backsheet applications.

Production Line Process:

Raw Material Processing:

Polyolefin resins (such as PE and PP) are dried and pre-treated to remove moisture and impurities, ensuring that no air bubbles or clumping occur during extrusion.

Extrusion and Forming:

The polyolefin resin is melted and extruded into film using an extrusion machine. Co-extrusion technology can also be employed to produce multi-layer composite films, enhancing the overall performance with an inner, outer, and middle layer structure.

Cooling and Shaping:

The extruded film is quickly cooled using cooling rolls or water tanks, solidifying it while maintaining its flatness and shape.

Stretching (Optional):

In some production lines, polyolefin backsheet films undergo both heat and cold stretching processes to improve mechanical strength and aging resistance.

Surface Treatment:

Surface treatments, such as corona or plasma treatment, are used to enhance film adhesion and performance.

Winding and Cutting:

The film is wound and cut to the desired dimensions, ensuring precise control over thickness and width, and properly packaged for transport.

Quality Inspection:

Rigorous quality inspections are performed to ensure that the film meets thickness, permeability, tensile strength, and thermal resistance standards.

Main Features:

Highly efficient automation to improve production efficiency.

Precise control over film material thickness and quality.

Excellent weather resistance, UV protection, and mechanical strength.

Energy-saving and environmentally friendly, complying with green manufacturing standards.

Applications:

Solar backsheet films

Seawater desalination and wastewater treatment

Lithium battery separators

Outdoor building membranes

Contact: Charles

Phone: 18861950103

E-mail: saley@gwell.cn

Whatsapp:+86-18861950103

Add: . 90# Shengfeng Road,Dafeng Economic Develepment Zone,YanCheng ,JiangSu ,China.

We chat